Extruder Duty Helical Gearbox

The Products :

Plastic Industry, at present, uses worm reduction gear boxes in extrusion and blow moulding plants, which creates many problems continous production works. Like oil leakage, over heating, noise, wear & tear of bronze worm wheel, etc...

In addition to that this gear box requires separate bearing bousing to withstand thrust load of screw. To over come this problem we have launched specially developed helical gear box with in-built thurst bearing, which gives you following advantages.

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is used.

- Cost saving.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided for better efficiency of gear box.

- No maintenance required except periodic oil level checking.

- Higher productivity compare to worm reducer.

Gear Body :

It is made of close grain cast iron, Which is absolutely dust proof & oil tight.

Gear :

Gears are Helical type-made of case iron, hardened alloy steel, Gear teeth are hobbed and profile ground for smooth & silent running.

Oil Seals :

Silicon oil seals are used to resist very high temperature resulting from the heaters on the barrel.

Bearings :

In addition to thrust bearing taper roller bearings of ample capacity are used to withstand thrust and radial loads.

Lubrication :

Lubrication is done by splash of oil, no separate care is required except periodic checking of oil level.

- Use proper grade of gear oil only.

- Change first filling of oil after two months of operation and then after every six months.

Cooling :

For KGT 125 & higher size, In addition to natural cooling, water cooling coil is given as standard fitment to imporve hea dissipation & efficiency.

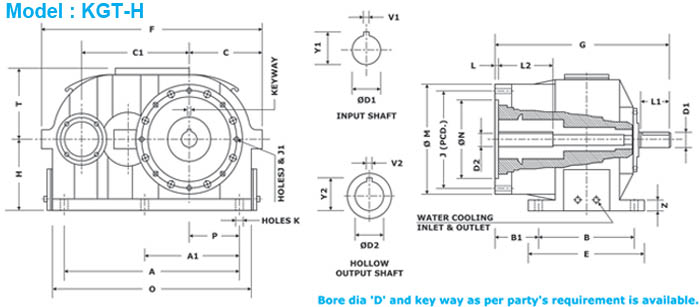

Model : KGT - H

GEAR BOX |

| Model |

Ratio |

| KGT 80 |

12.5:1 |

| KGT 130 |

13:1/6:1 |

| KGT 150 |

13:1/6.1 |

| KGT 160 |

13:1/9:1 |

| KGT 180 |

13:1/20:1 |

| KGT 200 |

13:1/9:1 |

|

GEAR BOX HOUSING DIMENSION |

| C |

C1 |

A1 |

A |

B |

B1 |

P |

O |

E |

H |

T |

F |

G |

ØK |

Z |

| 113 |

140 |

-- |

215 |

130 |

54.5 |

60

|

260 |

165 |

110

|

100

|

320 |

242 |

14

|

20 |

| 169 |

220 |

-- |

375 |

230 |

102 |

100

|

435

|

290

|

160

|

165

|

495

|

428

|

19

|

30 |

| 185 |

260 |

-- |

430 |

225 |

122 |

115

|

500

|

280

|

185

|

170

|

565

|

453

|

19

|

30 |

| 206 |

280 |

-- |

470 |

270 |

129 |

135 |

550 |

345 |

200 |

192 |

610 |

524 |

24 |

35 |

| 218 |

310 |

-- |

525 |

285 |

145 |

154 |

595 |

360 |

225 |

205 |

655 |

555 |

24 |

35 |

| 241 |

350 |

310 |

580 |

305 |

152 |

165 |

650 |

375 |

225 |

225 |

720 |

571 |

24 |

35 |

|

INPUT SHAFT |

| ØD1 |

L1 |

V1 |

Y1 |

| Ø16 |

40

|

5 |

18.5 |

| Ø30 |

80

|

8 |

34 |

Ø32

|

80

|

10 |

37 |

Ø38

|

95 |

10 |

43 |

Ø38

|

95 |

10 |

43 |

Ø48

|

95 |

14 |

55 |

|

GEAR BOX |

| Model |

Ratio |

| KGT 80 |

12.5:1 |

| |

|

| KGT 130 |

13:1/6:1 |

| KGT 130 |

13:1/6:1 |

| |

|

| KGT 150 |

13:1/6.1 |

| |

|

| KGT 160 |

13:1/9:1 |

| KGT 160 |

13:1/9:1 |

| |

|

KGT 180

|

13:1/20:1 |

| |

|

| KGT 200 |

13:1/9:1 |

|

OUTPUT SHAFT |

| ØD2 |

L2

|

V2 |

Y2 |

| Ø20 |

70 |

6 |

23 |

Ø25

|

70 |

6 |

28 |

| Ø35 |

125 |

10 |

40 |

| Ø40 |

125 |

10 |

45 |

| Ø40 |

125 |

10 |

45 |

| Ø50 |

125 |

10 |

45 |

| Ø50 |

150 |

12 |

54 |

| Ø55 |

150 |

12 |

59 |

| Ø60 |

150 |

14 |

65 |

| Ø70 |

150 |

16 |

75 |

| Ø80 |

190 |

16 |

85 |

|

MOUNTING FLANGE |

| ØM |

ØN |

J |

J1 |

L |

BRG. |

| 150 |

90 |

125 |

1/2"Thd. |

5 |

32309 |

| 150 |

90 |

125 |

1/2"Thd. |

5 |

32309 |

235

|

150 |

195 |

5/8"Thd. |

10 |

29416 |

235

|

150 |

195 |

5/8"Thd. |

10 |

29416 |

280

|

210 |

245 |

5/8"Thd. |

10 |

29416 |

| 280 |

210 |

245 |

5/8"Thd. |

10 |

29418 |

| 280 |

210 |

245 |

5/8"Thd. |

10 |

29420 |

| 280 |

210 |

245 |

5/8"Thd. |

10 |

29420 |

300

|

220 |

260 |

5/8"Thd. |

10 |

29422 |

| 300 |

220 |

260 |

5/8"Thd. |

10 |

29422 |

350

|

250 |

310 |

3/4"Thd. |

10 |

29426 |

|

Model : KGT - S

GEAR BOX |

| Model |

Ratio |

| KGT 110 |

12.5:1 |

| KGT 125 |

12.5:1 |

| KGT 140 |

12.5:1 |

| KGT 180 |

12.5:1 |

| KGT 225 |

12.5:1 |

| KGT 250 |

12.5:1 |

|

GEAR BOX HOUSING DIMENSION |

| C |

C1 |

A1 |

A |

B |

B1 |

P |

O |

E |

H |

T |

F |

G |

ØK |

Z |

| 140 |

190 |

160 |

310 |

150 |

154 |

80

|

350 |

180 |

125

|

145

|

430 |

399 |

14

|

25 |

| 155 |

215 |

170 |

355 |

170 |

141 |

95

|

400

|

200

|

140

|

175

|

475

|

406

|

14

|

25 |

| 175 |

240 |

260 |

400 |

190 |

146 |

130

|

440

|

220

|

160

|

185

|

530

|

456

|

14

|

30 |

| 215 |

305 |

240 |

505 |

230 |

161 |

135 |

565 |

270 |

200 |

240 |

665 |

546 |

24 |

35 |

| 260 |

385 |

290 |

635 |

270 |

213 |

165 |

705 |

320 |

250 |

285 |

825 |

648 |

24 |

45 |

| 290 |

430 |

315 |

705 |

310 |

228 |

180 |

785 |

370 |

280 |

310 |

925 |

703 |

24 |

50 |

|

INPUT SHAFT |

| ØD1 |

L1 |

V1 |

Y1 |

| Ø25 |

60

|

8 |

29 |

| Ø25 |

60

|

8 |

29 |

Ø35

|

80

|

10 |

40 |

Ø50

|

110 |

14 |

57 |

Ø50

|

110 |

14 |

57 |

Ø55

|

110 |

16 |

63 |

|

GEAR BOX |

| Model |

Ratio |

| KGT 110 |

12.5:1 |

| KGT 125 |

12.5:1 |

| KGT 140 |

12.5:1 |

| KGT 180 |

12.5:1 |

| KGT 225 |

12.5:1 |

| KGT 250 |

12.5:1 |

|

OUTPUT SHAFT |

| ØD2 |

L2

|

V2 |

Y2 |

| Ø32 |

110 |

10 |

36 |

| Ø40 |

125 |

12 |

44 |

| Ø50 |

140 |

14 |

55 |

| Ø70 |

150 |

16 |

75 |

| Ø90 |

150 |

25 |

98 |

| Ø100 |

190 |

25 |

108 |

|

MOUNTING FLANGE |

| ØM |

ØN

|

J

|

J1

|

L

|

BRG. |

| 220 |

120 |

185 |

M 16 |

10 |

29414 |

| 260 |

135 |

220 |

M 16 |

10 |

29414 |

| 275 |

200 |

240 |

M 16 |

10 |

29418 |

| 315 |

200 |

280 |

M 16 |

10 |

29422 |

| 350 |

270 |

310 |

M 16 |

10 |

29426 |

| 380 |

300 |

340 |

M 20 |

10 |

29430 |

|

Model : KGT (Single Stage)

GEAR BOX |

| Model |

Ratio |

| KGT 140 |

6:1 |

| KGT 160 |

6:1 |

|

GEAR BOX HOUSING DIMENSION |

| C |

C1 |

A |

B |

B1 |

P |

O |

E |

H |

T |

F |

G |

ØK |

Z |

| 163 |

140 |

310 |

140 |

89 |

110

|

360 |

180 |

160

|

148

|

415 |

334 |

25

|

25 |

| 200 |

160 |

355 |

140 |

105 |

136.5

|

400

|

190

|

190

|

175

|

460

|

366

|

30

|

30 |

|

INPUT SHAFT |

| ØD1 |

L1 |

V1 |

Y1 |

| Ø28 |

50

|

8 |

32 |

| Ø28 |

60

|

8 |

32 |

|

GEAR BOX |

| Model |

Ratio |

| KGT 140 |

6:1 |

| KGT 140 |

6:1 |

| KGT 160 |

6:1 |

|

OUTPUT SHAFT |

| ØD2 |

L2

|

V2 |

Y2 |

| Ø25 |

100 |

8 |

29 |

| Ø30 |

100 |

8 |

34 |

| Ø35 |

110 |

10 |

40 |

|

MOUNTING FLANGE |

| ØM |

ØN

|

J

|

J1

|

L

|

BRG. |

| 200 |

100 |

170 |

1/2"Thd. |

5 |

29413 |

| 200 |

100 |

170 |

1/2"Thd. |

5 |

29413 |

| 235 |

150 |

195 |

5/8"Thd. |

10 |

29415 |

|

Model : KGT - Y

GEAR BOX |

| Model |

Ratio |

| KGT 100 |

11:1/15:1 |

| KGT 150 |

12.5:1/6:1 |

| KGT 180 |

13:1/20:1 |

|

GEAR BOX HOUSING DIMENSION |

| C |

C1 |

A |

B |

B1 |

P |

O |

E |

H |

T |

F |

G |

ØK |

Z |

| 114 |

180 |

285 |

105 |

119 |

85

|

320 |

145 |

137

|

103

|

365 |

346 |

15

|

25 |

| 169 |

260 |

450 |

220 |

109 |

142 |

495 |

180 |

195 |

165 |

525 |

429 |

19 |

30 |

| 208 |

310 |

520 |

260 |

145 |

154

|

585

|

360

|

225

|

180

|

635

|

591

|

24

|

35 |

|

INPUT SHAFT |

| ØD1 |

L1 |

V1 |

Y1 |

| Ø28 |

50

|

8 |

32 |

| Ø32 |

80 |

10 |

37 |

| Ø38 |

95

|

10 |

43 |

|

GEAR BOX |

| Model |

Ratio |

| KGT 100 |

11:1/15:1 |

| KGT 100 |

11:1/15:1 |

| KGT 150 |

12.5:1/6:1 |

| KGT 150 |

12.5:1/6:1 |

| KGT 180 |

13:1/20:1 |

|

OUTPUT SHAFT |

| ØD2 |

L2

|

V2 |

Y2 |

| Ø25 |

100 |

8 |

29 |

| Ø30 |

100 |

8 |

34 |

| Ø40 |

125 |

10 |

45 |

| Ø50 |

125 |

12 |

55 |

| Ø60 |

150 |

12 |

65 |

|

MOUNTING FLANGE |

| ØM |

ØN

|

J

|

J1

|

L

|

BRG. |

| 190 |

110 |

165 |

1/2"Thd. |

10 |

29413 |

| 190 |

110 |

165 |

1/2"Thd. |

10 |

29413 |

| 235 |

150 |

195 |

5/8"Thd. |

10 |

29416 |

| 235 |

150 |

195 |

5/8"Thd. |

10 |

29416 |

| 300 |

220 |

260 |

5/8"Thd. |

10 |

29422 |

|

Kumaro Gearbox assembly with extruder machine & motor

Manufacture, Exporters and Supplier

GLOBAL TECHNOLOGIES, Ahmedabad.